Will Oil degreasing additive affect the coating effect of metal surfaces?

2024-05-21 15:30

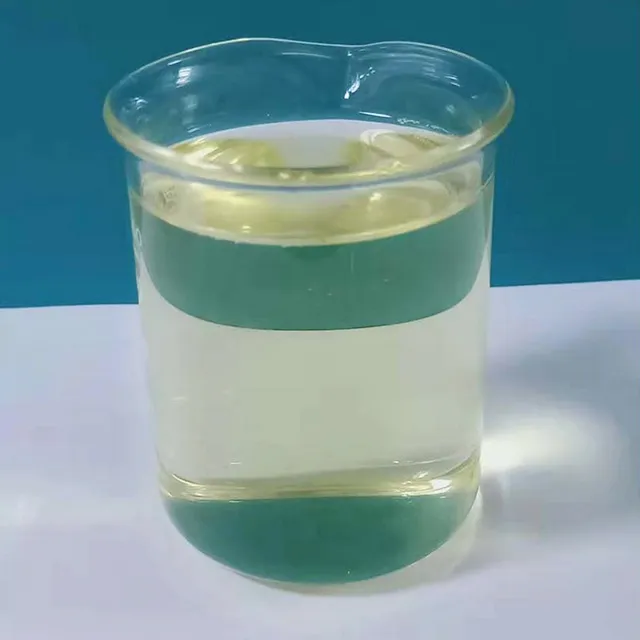

In the metal surface treatment process, Oil derosination additive is a commonly used chemical that is widely used to remove oil stains on metal surfaces to improve surface quality and coating effects. However, there are certain doubts and concerns about whether Oil degreasing additive will affect the coating effect of metal surfaces.

Today, we will delve into this issue, answer the concerns of consumers and the industry, and reveal the impact of oil degreasing additive on the coating effect and its reasons.

1. Effect of Oil degreasing additive on painting effect

First, we need to understand the impact of Oil derosination additive on the coating effect. Oil degreasing additive is mainly used to remove oil stains and impurities from metal surfaces to improve surface cleanliness and coating adhesion. However, if the oil degreasing treatment is not complete or there is too much oil degreaser residue, it may affect the adhesion of the primer and the quality of the coating, resulting in poor coating results and even problems such as peeling and blistering of the coating.

2. Effect of oil degreasing additive residue

Oil degreasing additive residue is one of the main factors affecting the painting effect. If the oil degreasing treatment is not complete or there is too much oil degreaser residue, a film may form on the metal surface, affecting the adhesion of the paint primer and the quality of the coating. In addition, oil degreaser residues may react chemically with the coating primer, affecting the curing and hardening of the coating primer, resulting in a decrease in the adhesion and durability of the coating.

3. Importance of oil degreasing treatment

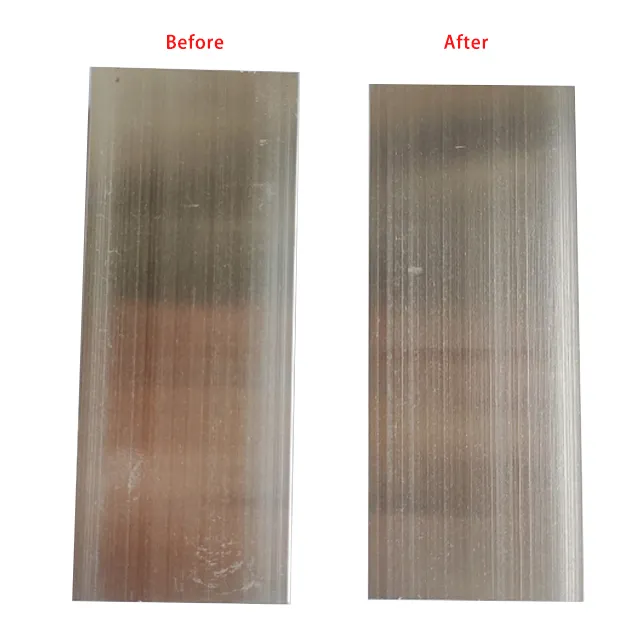

Faced with the impact of Oil derosination additive on the coating effect, we need to pay attention to the importance of oil degreasing treatment. Correct oil degreasing treatment can effectively remove oil stains and impurities on the metal surface, improve surface cleanliness and coating adhesion, and ensure the quality and stability of the coating effect. Therefore, during the metal surface treatment process, the process parameters and operating requirements of oil degreasing treatment need to be strictly controlled to ensure that the usage amount and residual amount of oil degreasing agent meet the standard requirements.

4. Cooperation of technology and equipment

In addition to strictly controlling the process parameters and operating requirements of oil degreasing treatment, the coordination of technology and equipment is also the key to ensuring the coating effect. For example, advanced cleaning equipment and processes can be used, coupled with appropriate oil degreasing agents and process control systems, to ensure thorough and uniform oil degreasing treatment and avoid the occurrence of residue and contamination problems.

5. Preparation before painting

Finally, before painting, sufficient preparation work needs to be carried out, including surface cleaning, degreasing, surface treatment, etc. Before painting, the metal surface needs to be thoroughly cleaned to remove oil and impurities to ensure surface finish and coating adhesion. At the same time, the oil degreasing process needs to be strictly tested and controlled to ensure that the usage amount and residual amount of oil degreasing agent meet the requirements to avoid affecting the painting effect and quality.

Conclusion: Scientific management ensures the painting effect

In summary, the residue of Oil derosination additive may affect the coating effect on the metal surface, but through scientific management and technical control, its impact on the coating effect can be minimized and the quality and stability of the coating effect can be guaranteed. .

In future development, we should further strengthen the research and management of oil degreasing treatment, promote the improvement and innovation of coating processes, and provide better technical support and guarantee for the coating of metal products.